So, one of the conclusions I arrived at after my previous attempt at mounting the fuel filler neck in the front of the freeway was that I needed to rework how the fiberglass is laid out so the filler mount is horizontal. Basically, I need to inset a pocket into the fiberglass nose which it can sit down into.

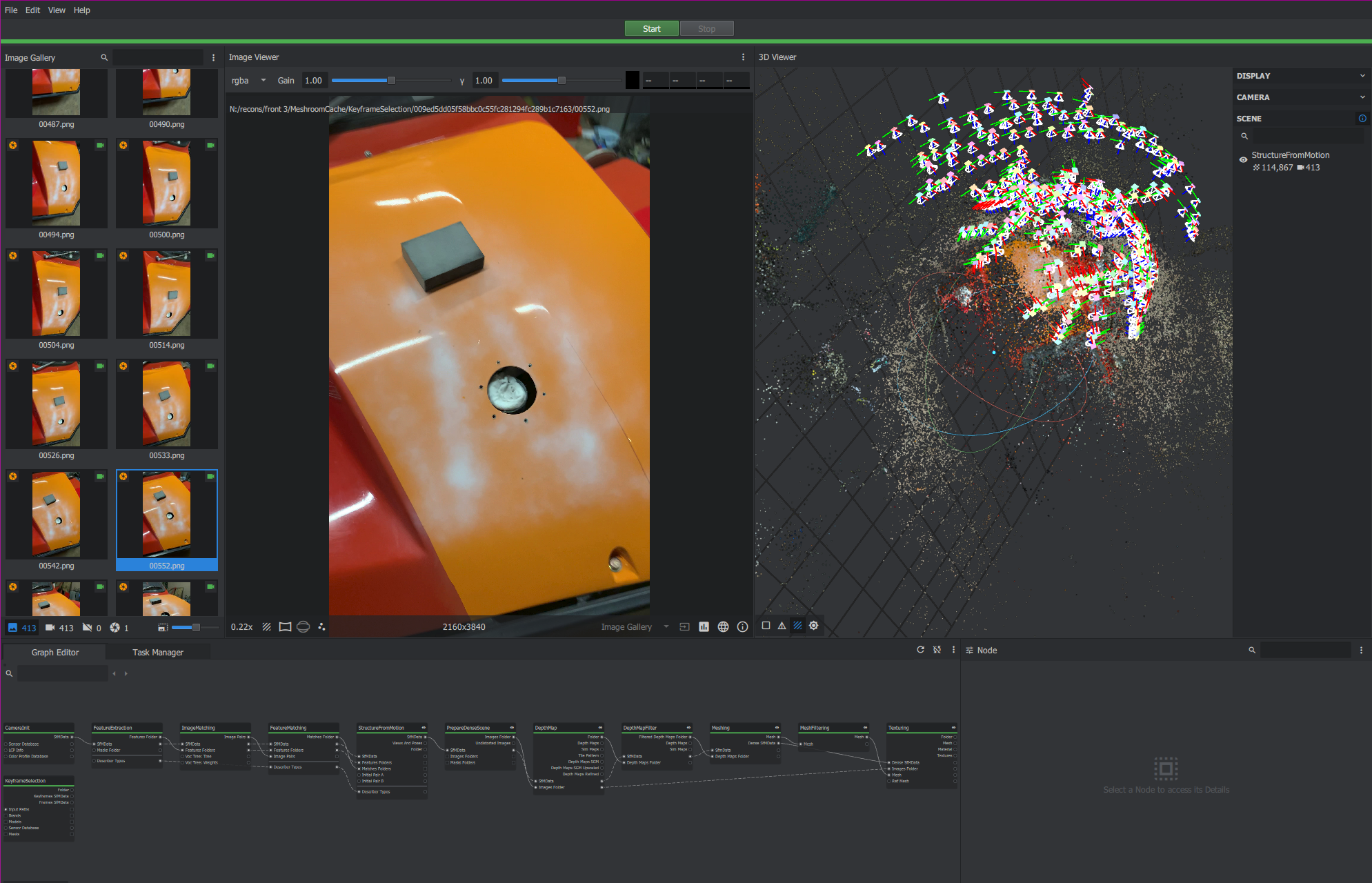

So, I’ve got a fairly well understood process for matching the weird surface curves at this point.

- Spray with 3d scanning spray.

- Put a object of known size in the frame

- Wave my phone slowly around and take a video

- Shove into meshroom. Extract frames from the video, and run the default mesh pipeline

- Bring geometry into Fusion 360. Fit a surface to the (rough) mesh.

- Design a negative of the new body shape. Also design a template that will key off existing geometry to figure out where to cut

- 3D print the mold

- Paint + wax the mold

- Fiberglass!

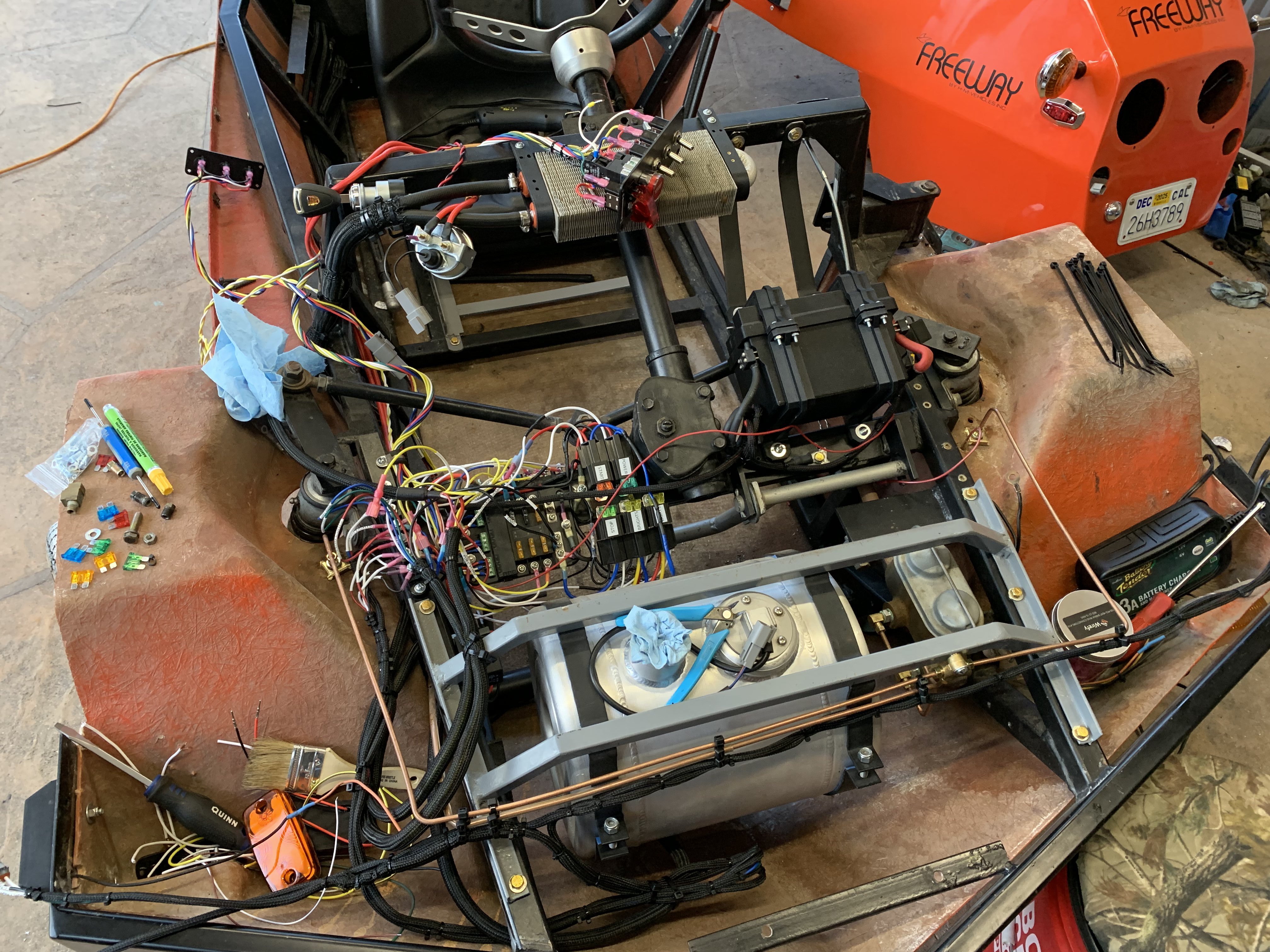

I took the body off, and expanded the fuel filler hole to fit the new geometry.

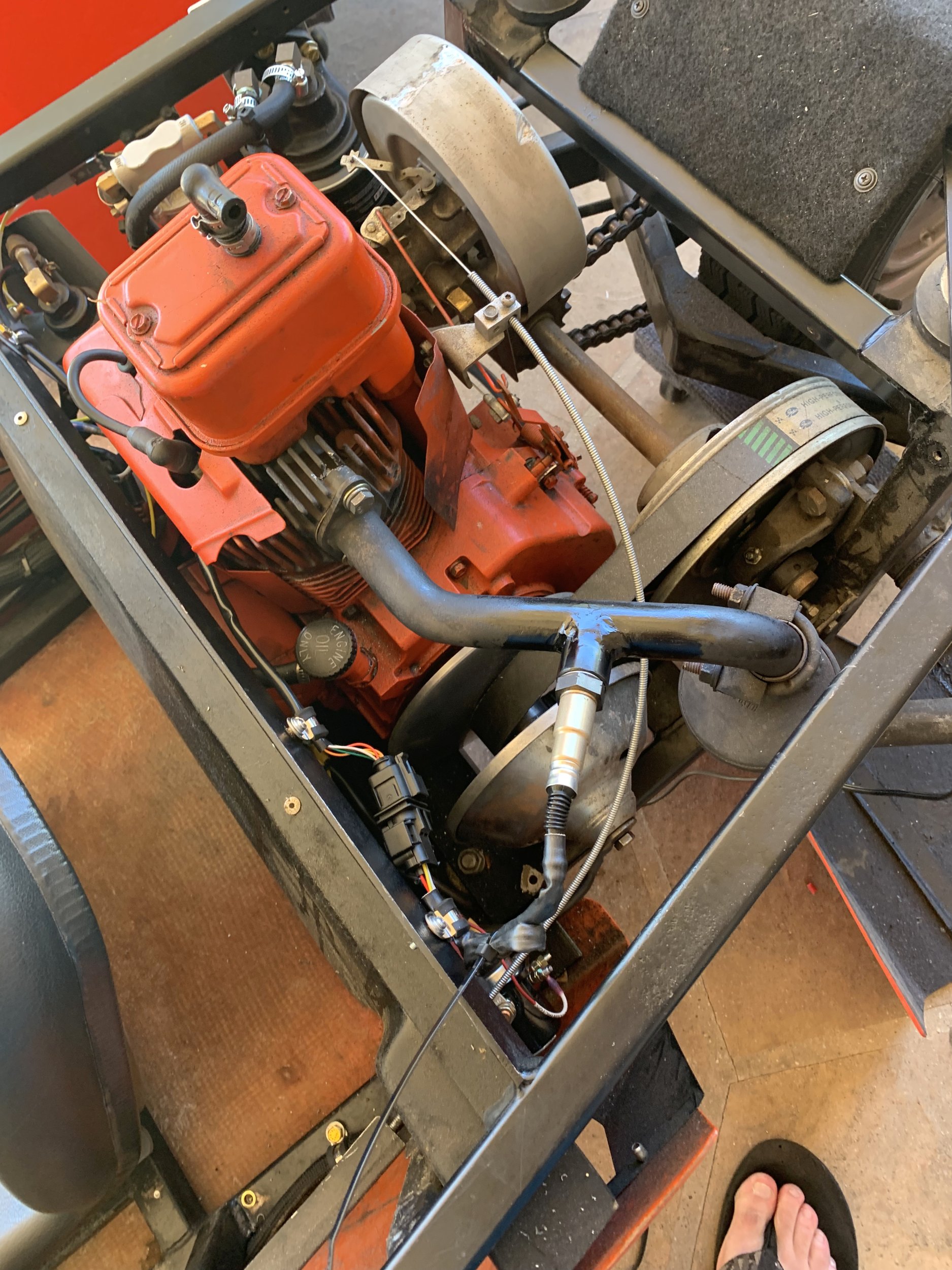

Since I had the body off, I also took the opportunity to finally powerwash the underside of the top-half. In particular, the rear area over the engine had a light film of oil and road-grime that had been annoying me.

I then sanded out the existing fiberglass to give a proper surface finish for the newly added glass to properly adhere. I also feathered the fiberglass around the mold (grey lump) in the below image to make things join more cleanly.

I also went around with a smaller sanding pad and cleaned up a bunch of areas on the underside where there was crappy fiberglass work from the manufacturer:

When HMV was bonding the engine cover section into the overall body, they really half-assed the fiberglass mat in the tail section. While this is really not a actual issue with the body from a structural perspective, the poor workmanship bothered me, so I sanded these back as well and patched them in with small bits of fiberglass cloth.

One thing I think is pretty clear at this point is that while I appreciate the Freeway for what it is, I’m not at all precious about it being “original” or anything. One part I particularly dislike is the rear engine/wheel cowling area. It both looks pretty terrible (in my opinion) and the fiberglass in that area is also very thin and starting to fail.

The shape of it also makes installing/removing the body top a lot more annoying.

I took this opportunity to cut a bunch of it away entirely.

I think this improves the body-lines a lot, and also will make access to the rear wheel and engine area a lot more convenient. I also feathered the fiberglass edges around the original fuel filler neck hole, so I can patch that in the future.

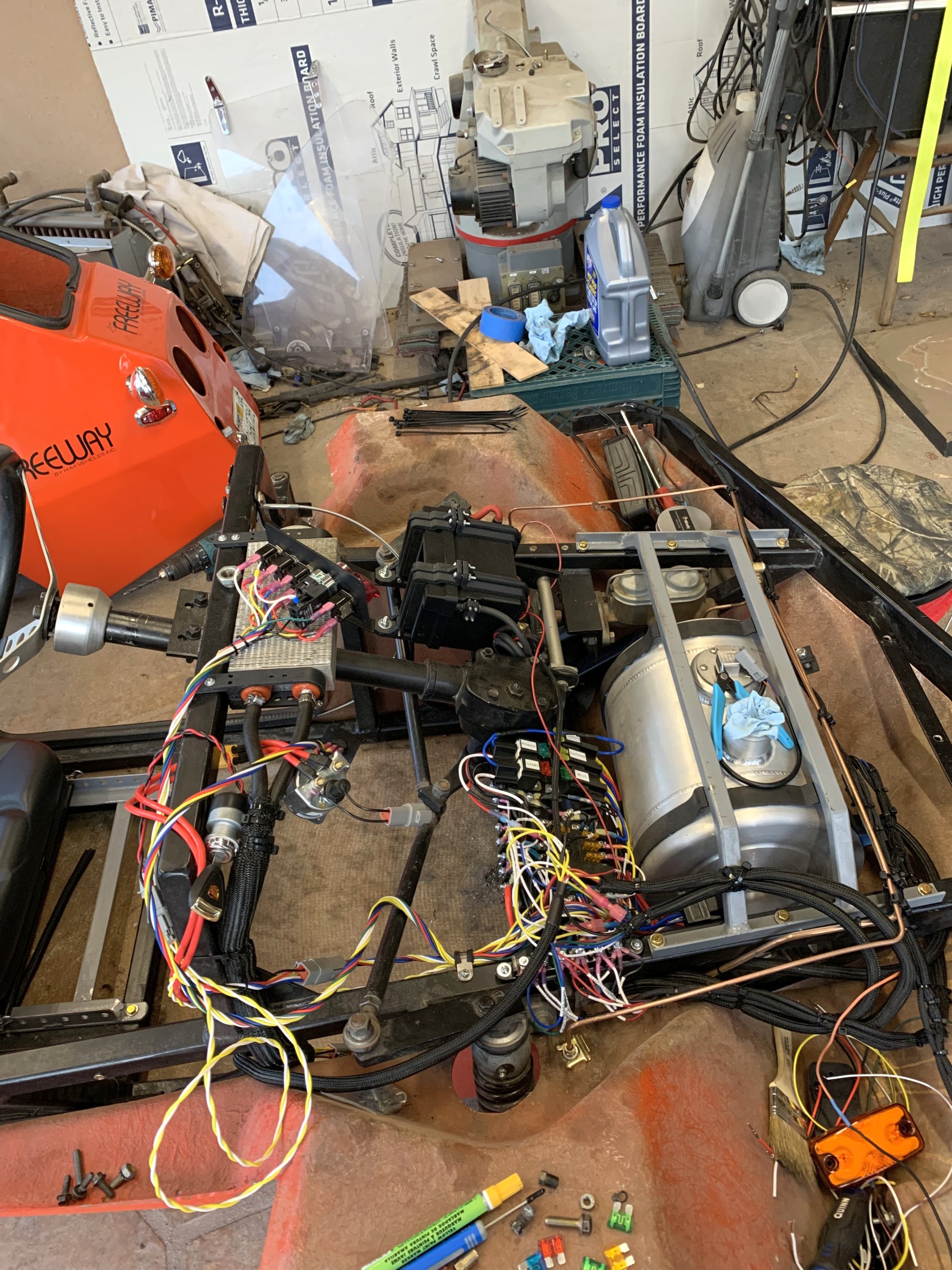

So, the final issue I had here is that after I had done all the fiberglass work, I was powerwashing the body again, primary to remove some of the vinyl stickers I had been experimenting with, and well, apparently whoever did the orange/red paint on top of the original red paint did a completely shit job.

The powerwasher caught under an edge and wound up lifting a huge section of the paint layer in seconds. There is about zero adhesion between the primer layer on top of the original paint and the color coat (the clearcoat is also barely adhering, but that’s not the issue here).

Anyways, after a hour or so with the powerwasher, the entire front end is basically stripped of paint.

You can also see the newly shaped fuel filler hole here. The mold came out quite well, though I had to pry a bit to get it to finally pop out.

Considering this was effectively the first time I’ve ever attempted fiberglass molding, I’m pretty damn happy with the result. I think I should have used a couple more coats of partall wax (or I wasn’t layering it on thick enough), but it came out without issue in the end, despite pulling a bit of the paint from the mold surface. I’m also super encouraged by the idea of making a mold for a rear internal fender.

At this point, I’ve more or less concluded I’m going to have to either repaint the entire upper body section, or have another go at vinyl wrapping it. The vinyl wrap sticks SUPER well to a surface with a bit of a key to it, and I think most of my trouble with my previous attempt was that I thought I needed to do the entire area with one single vinyl section. I believe if I do the coating in multiple sections, it should be a lot more tractable. It’ll have seams, sure, but hopefully I can live with that.

I don’t have a lot of pictures of the work here (or most of the fiberglass stuff), since it’s a very messy process and I’m wearing gloves with either resin or lots of fiberglass dust on them for most of it.