One of the major things needed on the freeway to make it properly drivable is replacing the fuel tank, since it has a vapor leak /somewhere/.

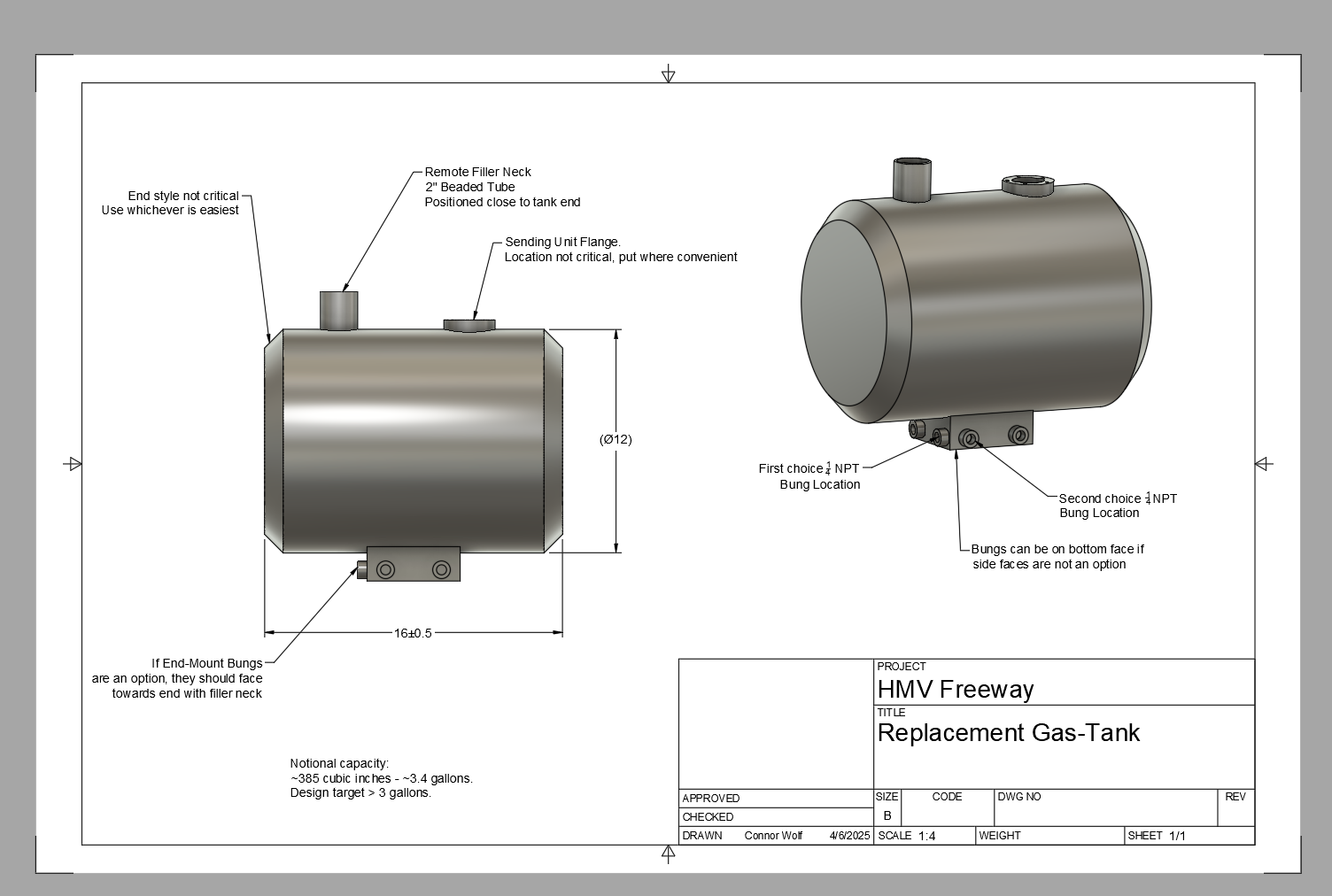

Anyways the fuel tank was kind of a messy story. I designed a tank that was supposed to fit next to the battery behind the seat. This lead to a squat, large tank (10” dia by 12” long).

I will say I ordered the seat from Bam Industries / https://spunaluminumgastanks.com. Apparently you can just email them a custom tank design (assuming it’s made with their standard fittings), and it effectively costs no more then any of the tanks from their website with the same feature set.

This tank wound up being $359 shipped, with all the tweaks I specified.

Once the tank was ordered, and before it showed up, I lowered the seat, which lead to me moving it backwards as well to improve driving comfort. I also started considering moving the battery to the front of the vehicle, since I know at least one other person has done that. That means that the tank I had already ordered was now designed to accommodate constraints that no longer existed, and the new location of the seat meant it would be fiddly to fit and require me to adjust the seat forwards enough that it was less comfortable.

The tank arrived, and looks really nice:

My only real complaint is that the mounting rings they ship with the tank have no paint, and are plain steel, so you have to coat them somehow. Otherwise, it’s a very nice unit.

At this point, I had the body off, and my housemate asked why I didn’t move the tank up to the big open area in the front.

This entails even more changes, since the tank will fit fine up front if I cut out the integrated heatlight bucket. I also have to rework a bunch of the brake lines since the tank will now go right where they cross from the right to left hand side of the vehicle.

Anyways, a bunch of fiddling and mockup later, I used terriblwelder to put together a cross-member mounting frame to hold the tank up front. I continue to be rather surprised by how capable even the cheapest flux-core welder is.

The cross member is bolted to the existing freeway frame with rivnuts and 1/4-20 grade 8 bolts. I also used them to hold the mounting hoops to the cross-member. I’m OK with using rivnuts here since the bolts are all located in shear in the case of a collision anyways, and rivnuts have a much stronger pull-out force resistance then I initially thought (1/4-20 has ~500 lbs pull-out in thin material!).

The tank is offset to the right hand to clear the master cylinder (which mounts in the hole in the bracket on the left-hand side, right hand of the above image).