So, one area where I let things get a bit out of hand was the gauge situation on the freeway.

These originally came with 4 gauges: Speed, oil temp, fuel level, and battery current (plus and minus).

The Speedo is GPS-based. The original speedometer got water-damaged somehow, so the previous owner (tried) to replace it with a GPS unit. Somehow, when I took possession of the vehicle, it only worked when the engine was not running. I’m not sure how that was managed, I didn’t bother tracing any of the wiring since I have an original wiring diagram, and was planning on replacing all the wiring anywas.

Since I’m a nerd, I added a tachometer, a voltmeter and one more.

So one of my housemates is a jerk, and made a sarcastic comment about a O2 sensor. Well….

(Trust me, these welds looked really terrible before I ground them nice.)

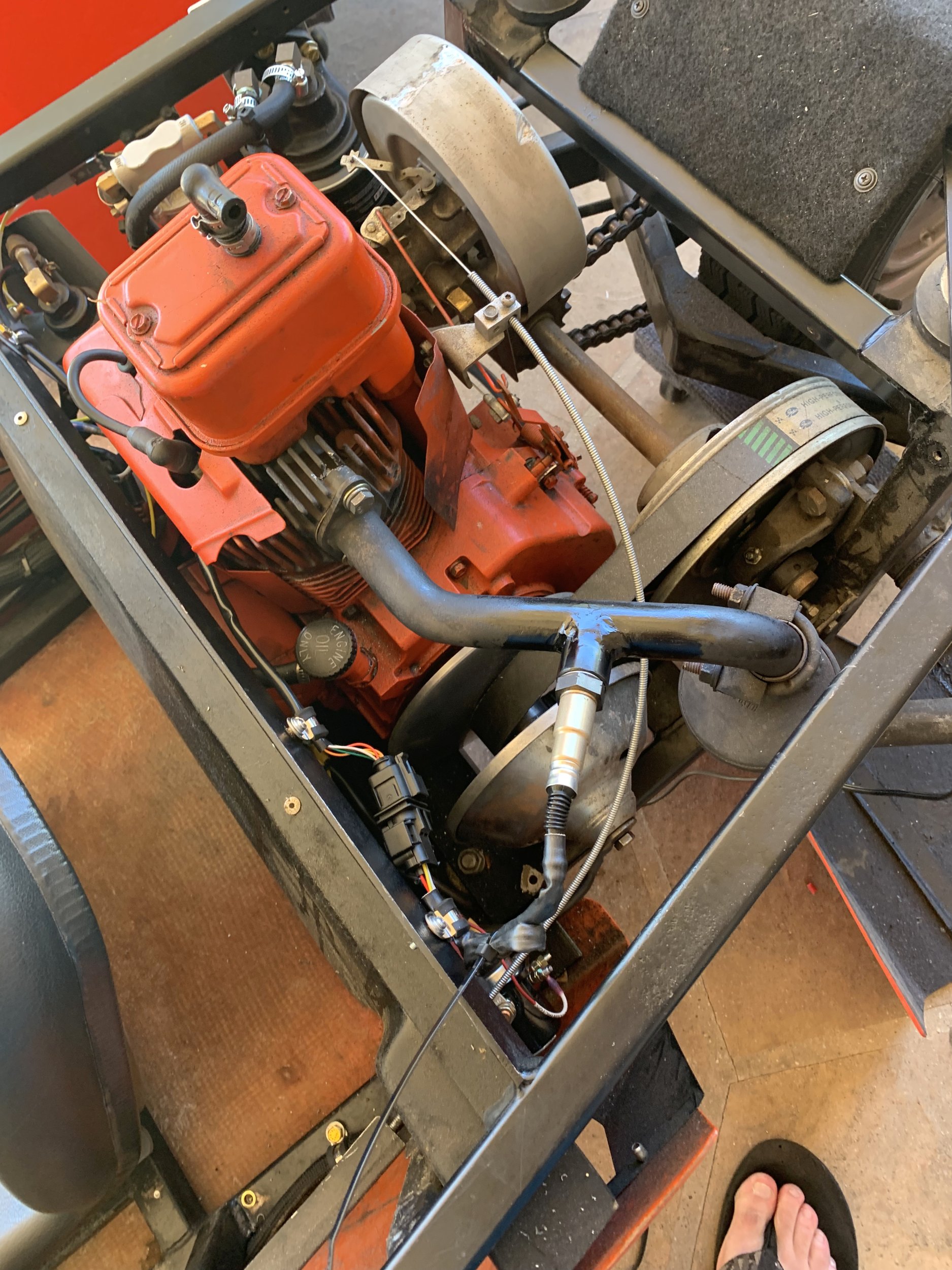

Terriblwelder strikes again, and I now have a O2 bung in the exhaust, and a Chinese clone of an AEM 30-0300 Wideband AFR gauge installed in it.

I had to shop around a fair bit for a bung that would work here, since most O2 sensor bungs have the sensor protrude maybe 1/4” into the exhaust pipe. Since the exhaust pipe here is about 1” ID, that would substantially occlude the pipe.

I managed to find a bung where the O2 sensor tip just barely peeks into the pipe ID when it’s fully screwed in. This isn’t a high performance application, I can handle the sensor response being maybe a tiny bit sluggish.

I can also confirm that the carb tuning is terrible. It idles around 10:1 AFR currently, which makes sense (it smells rich just running). I’ve not had it under load running yet.

——–

I also took the opportunity to helicoil one of the exhaust flange bolt holes, as it was on the edge of the threads being completely gone (the bolt in it did screw in, but it could rotate continuously with just a bit of resistance).